We establish quality targets for all employees, and we constantly work to improve quality. We are certified to the ISO 9001, an international standard for quality management system.

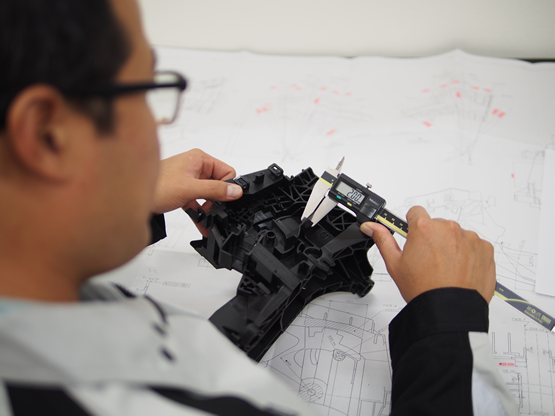

Since the founding of the company, we have specialized in prototype molds and prototypes produced with precision plaster casting for the automotive industry.

We believe that our achievements in maintaining the required quality in automotive functional parts and prototypes is the very source of our strength in product quality.

In addition to the required level of quality, we do our utmost to satisfy requirements for functional parts, traceability, and speed of delivery.

Our activities are constantly directed at maintaining quality, and maintaining the trust of the customer.

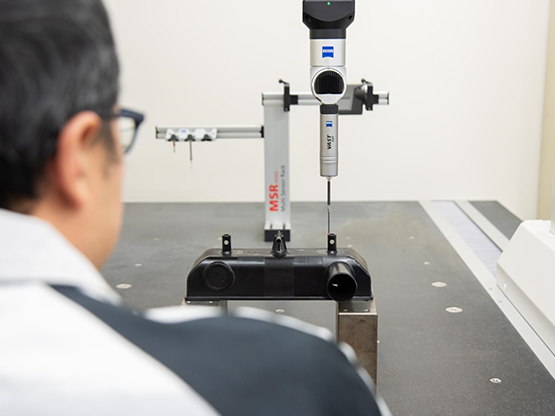

Product is measured and inspected with 3D measuring equipment, and the data is fed back to the mold making process to improve accuracy and quality.

We also have facilities for product inspection from 3D drawings using CATIA V5, UG-NX, and I-DEAS.

Once we understand customer quality requirements, we produce quality products which meet customer requirements. We are constantly engaged in activities directed at maintaining and improving quality to meet customer satisfaction.