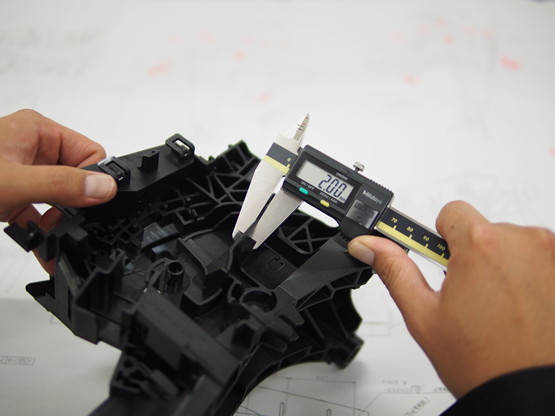

Since its establishment, Alphatec has been designing and manufacturing plastic prototype molds and castings in its specialized field of prototype development (specializing in molds) for automotive parts.

We have manufactured and shipped more than 3,000 molds so far, and have been involved in the development of a wide range of products.

Our strengths in technology, short delivery times, and quality have been developed through many years of experience.

Our prototype molds require a minimum time to T1 of 2.5 - 3 weeks, and a minimum of 3 weeks for cast products. Prototype development naturally has tight delivery schedule.

Alphatec’s system ensures delivery and technology proposals in the shortest possible time.

We also boast rapid response in all our sales activities, from quotes to delivery.

Alphatec's mission - changing NO to YES to solve difficult tasks together with manufacturers.

Do you have any problem? Contact us without hesitation. We take pride in providing the optimum technical solutions to your problems.

Alphatec is certified according to ISO9001. Our system maintains quality through the use of a wide range of measuring instruments including 3D measuring equipment.(CMM)

Our high level of quality is a product of our experience, and is evaluated highly by our customers.