A technique in which plastic is melted by bringing it into contact with a high-temperature plate, and then pressed into contact to join before the molten part cools.

This ensures high-strength welding, and highly reliable airtight welding.

We handle many parts produced from plastic molds, and we can achieve quicker development times and higher quality with the use of this hot-plate welding in-house.

What is spin welding?

Parts are welded by frictional heat due to rotation. This is a method of fixing the lower part to the jig, pressuring and welding the part attached to the upper jig while rotating.

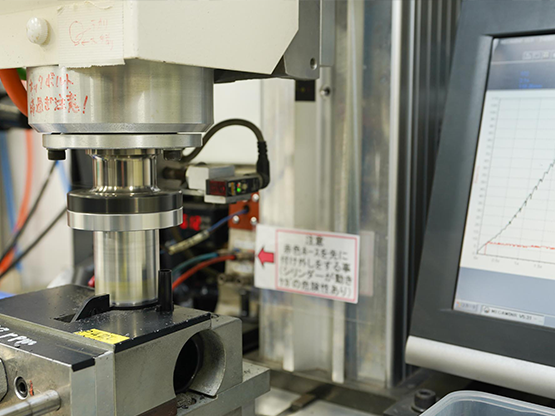

We check airtightness of welded products using helium gas leak testing equipment.

The welding and leak test conditions are recorded for each product and are traceable.